Table of Contents

- Introduction

- The Power of MOF-525

- Advancing Carbon Capture Solutions

- Scaling Up for Greater Impact

- UVA’s Commitment to Green Energy

- Conclusion

Introduction

Researchers at the University of Virginia have made a groundbreaking advancement with the novel material MOF-525. This member of the metal-organic frameworks (MOFs) family holds immense promise for carbon capture and conversion technologies. By developing a scalable manufacturing process using solution shearing techniques, the team has enabled MOF-525 to be applied over large areas, significantly enhancing its effectiveness in capturing and converting carbon dioxide (CO2) into valuable chemicals. This breakthrough offers practical solutions for large-scale applications, addressing major environmental and energy challenges.

The Power of MOF-525

MOF-525 is a standout in the metal-organic frameworks class due to its ultra-porous, crystalline structure composed of 3D networks of nanoscale cavities. These cavities create a vast internal surface area that acts like a sponge, capable of trapping various chemical compounds. The real innovation comes from making these MOFs cover large areas, which opens up new applications such as creating membranes for carbon capture and electrocatalytic conversion in one system. This approach could eliminate the need for burning fossil fuels that produce CO2, creating a direct bridge between renewable energy sources and chemical synthesis.

Advancing Carbon Capture Solutions

Assistant Professor of Chemical Engineering Gaurav “Gino” Giri’s lab group has been at the forefront of this advancement. Their process involves mixing the MOF components in a solution, which is then spread across a substrate with a shearing blade. As the solution evaporates, chemical linkages form the MOF as a thin film on the substrate. This method effectively produces an all-in-one membrane for carbon trapping and conversion. MOF-525 can catalyze reactions using minimal energy input, transforming CO2 into carbon monoxide—a valuable chemical for manufacturing fuels, pharmaceuticals, and other products. This innovative approach to carbon capture and conversion could revolutionize how industries manage greenhouse gas emissions.

Scaling Up for Greater Impact

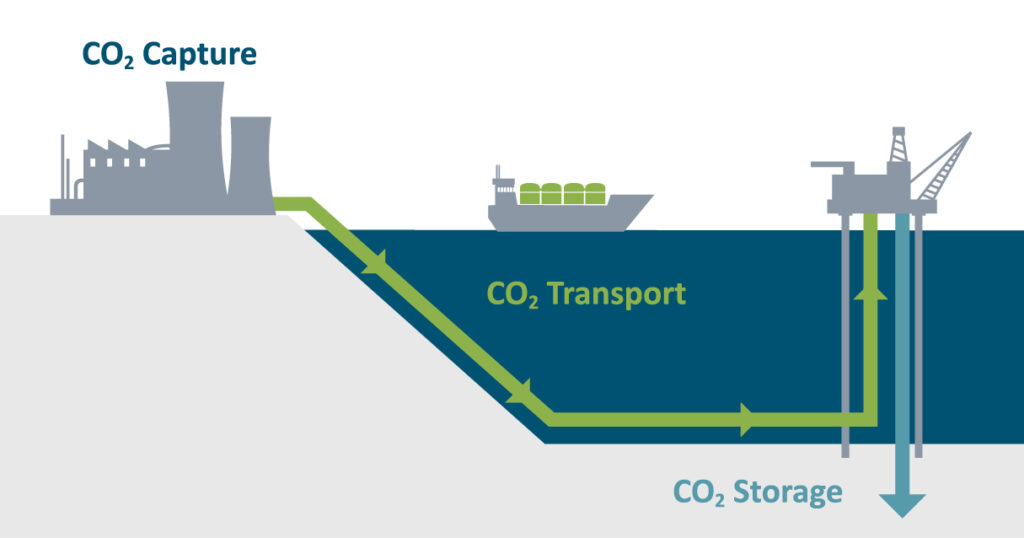

Scaling up the application of MOF-525 is crucial for maximizing its impact. “The bigger the membrane, the more surface area you have for the reaction, and the more product you could get,” said Prince Verma, a recent Ph.D. graduate from Giri’s lab. By increasing the shearing blade width, the process can be scaled to meet various size requirements. This approach is particularly relevant for CO2 conversion, as carbon capture is widely used to reduce industrial emissions or remove atmospheric CO2. Traditional methods often result in CO2 being stored indefinitely underground, offering minimal commercial return. However, MOF-525 provides a more practical and valuable solution.

UVA’s Commitment to Green Energy

The University of Virginia (UVA) is deeply committed to advancing green energy solutions. The process of accelerating reactions through catalysis, particularly electrocatalysis, is essential for a sustainable energy future. Recognizing this, UVA has invested $60 million in catalysis research as part of its Grand Challenges Investments. Giri collaborated with UVA Associate Professor of Chemistry Charles W. Machan to leverage this expertise. “The materials from Gino’s lab help us understand how to enable new, scalable technologies for capture and conversion, which we’re going to need to address the environmental challenges posed by current carbon dioxide concentrations in the atmosphere and rate of emissions,” Machan said. This collaboration underscores UVA’s dedication to finding innovative solutions for global environmental challenges.

Conclusion

The scalable fabrication of MOF-525 represents a significant advancement in carbon capture and conversion technologies. By making large-scale applications feasible, this breakthrough offers a practical solution for addressing greenhouse gas emissions and meeting the world’s energy needs. The research, supported by various institutions including the UVA Environmental Institute and the U.S. Department of Energy, highlights the potential for MOF-525 to play a critical role in the transition to a sustainable energy future. This development marks a promising step forward in the fight against climate change and the quest for cleaner energy.

The research findings were published in the American Chemical Society journal Applied Materials & Interfaces, showcasing the collaborative efforts of numerous scientists and institutions.

1 Comment

Pingback: Cyndi Lauper • Concert Tour