“Discover the comprehensive guide to pocket tech gauges in 16ths. Learn about their accuracy, applications, maintenance, and more. Perfect for professionals in woodworking, metalworking, and engineering.”

Table of Contents

Introduction Of Pocket Tech Gauges

Pocket tech gauges are essential tools for professionals in various fields, from woodworking to metalworking and engineering. These compact, precise instruments are designed to measure small dimensions accurately, often in 16ths of an inch. This guide will delve into the intricacies of pocket tech gauges, exploring their importance, applications, maintenance, and more.

Measurement Accuracy in Pocket Gauges

Precision in Pocket Gauges

Measurement accuracy is crucial in many industries. Pocket tech gauges that measure in 16ths of an inch provide the fine detail necessary for tasks requiring high precision. This accuracy ensures components fit together perfectly, reducing waste and improving overall product quality.

Benefits of High Precision

Accurate measurements lead to better fitting parts, higher quality products, and increased efficiency. In industries like aerospace or automotive manufacturing, where precision is paramount, pocket tech gauges are indispensable.

Materials and Durability

Common Materials

Pocket tech gauges are typically made from stainless steel, aluminum, or hardened plastic. Each material offers different benefits, such as corrosion resistance, lightweight properties, and durability.

Stainless Steel

Stainless steel is a popular choice for pocket gauges due to its durability and resistance to corrosion. This material can withstand harsh environments, making it ideal for both indoor and outdoor use. Stainless steel gauges are also resistant to wear and tear, ensuring long-term accuracy.

Aluminum

Aluminum gauges are lightweight and easy to handle, making them a good choice for applications where portability is important. While not as durable as stainless steel, aluminum gauges can still provide accurate measurements if used carefully and maintained properly.

Hardened Plastic

Hardened plastic gauges are less expensive and lightweight, making them suitable for basic applications. However, they may not offer the same level of durability and precision as metal gauges. They are best used for light-duty tasks and in environments where the gauge is less likely to be subjected to heavy wear.

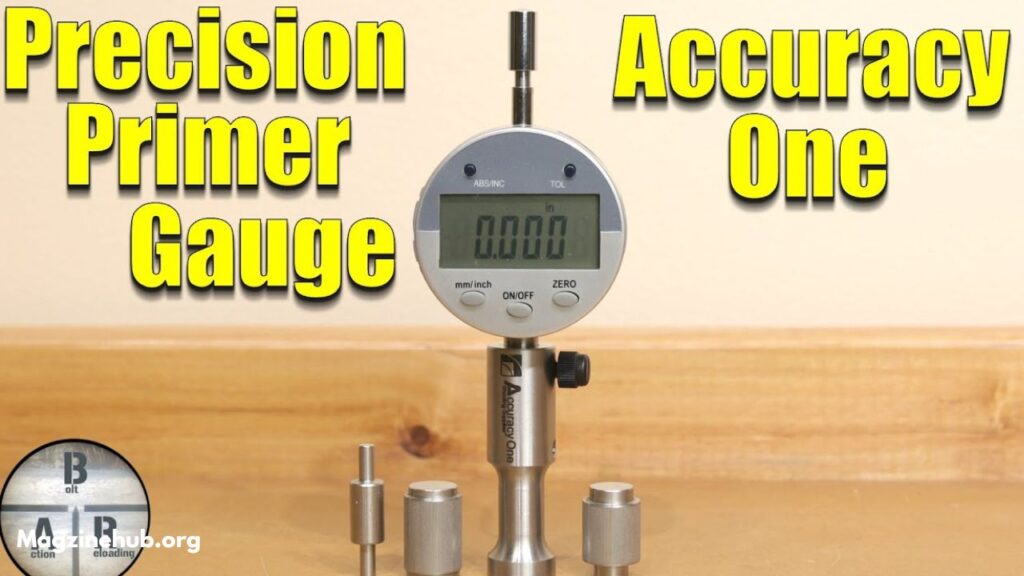

Digital vs. Analog Pocket Gauges

Digital Gauges

Digital pocket gauges offer ease of use and enhanced precision. They often come with features like backlit displays, data storage, and connectivity to mobile apps for recording measurements.

Advantages of Digital Gauges

- Easy to Read: Digital displays provide clear, easy-to-read measurements, reducing the likelihood of human error.

- Data Storage: Many digital gauges can store measurement data, which is useful for keeping records and conducting analyses.

- Connectivity: Advanced digital gauges can connect to smartphones and tablets, allowing for real-time data transfer and remote monitoring.

Disadvantages of Digital Gauges

- Battery Dependency: Digital gauges require batteries, which need to be replaced or recharged regularly.

- Higher Cost: Digital gauges tend to be more expensive than their analog counterparts due to the added technology.

Analog Gauges

Analog gauges, while less technologically advanced, are favored for their simplicity and reliability. They don’t require batteries and are often more durable in harsh environments.

Advantages of Analog Gauges

- Durability: Analog gauges are typically more rugged and can withstand harsh conditions better than digital gauges.

- No Battery Required: These gauges do not rely on batteries, making them reliable for long-term use without the need for power.

- Cost-Effective: Analog gauges are generally more affordable than digital ones.

Disadvantages of Analog Gauges

- Reading Errors: Analog gauges can be harder to read accurately, especially in low-light conditions.

- Lack of Features: They do not offer the advanced features available in digital gauges, such as data storage and connectivity.

Comparing the Two

Both digital and analog gauges have their place. Digital gauges are suitable for tasks requiring quick, precise measurements and data recording, while analog gauges are better for rugged environments and simpler tasks. The choice between digital and analog depends on the specific needs of the user and the conditions in which the gauge will be used.

Applications in Various Industries

Woodworking

In woodworking, pocket tech gauges are used to measure the thickness of materials, ensuring that cuts are precise and joints fit together seamlessly. Measuring in 16ths of an inch provides the accuracy needed for fine woodworking projects.

Measuring Thickness

Woodworkers often use pocket gauges to measure the thickness of boards and veneers. Accurate measurements are essential for creating uniform pieces and ensuring that joints fit snugly.

Setting Up Tools

Pocket gauges are also used to set up and adjust woodworking tools, such as saw blades and routers. Precise measurements help ensure that tools are correctly aligned, leading to cleaner cuts and improved overall results.

Metalworking

Metalworkers use pocket gauges to measure the dimensions of metal components accurately. This precision is critical for creating parts that fit together perfectly in machinery and structures.

Fabrication and Assembly

In metalworking, pocket gauges are used to measure the dimensions of parts during fabrication and assembly. Accurate measurements ensure that components fit together correctly, reducing the need for rework and improving the quality of the finished product.

Quality Control

Pocket gauges are also used in quality control processes to verify that parts meet specified tolerances. This ensures that finished products are consistent and meet industry standards.

Engineering

Engineers rely on pocket tech gauges for precise measurements during the design and manufacturing process. Accurate measurements ensure that all components meet strict specifications and standards.

Design and Prototyping

During the design and prototyping phases, engineers use pocket gauges to measure the dimensions of prototypes and ensure that they match design specifications. This helps identify and correct any issues before moving to full-scale production.

Manufacturing and Inspection

In manufacturing, pocket gauges are used to measure components and assemblies, ensuring that they meet design specifications. They are also used in inspection processes to verify the accuracy of finished products.

Calibration and Maintenance

Importance of Calibration

Regular calibration is essential to maintain the accuracy of pocket tech gauges. Over time, wear and tear can cause gauges to become less accurate, leading to measurement errors.

Calibration Procedures

Calibration involves comparing the gauge to a known standard and making adjustments as necessary. This process ensures that the gauge provides accurate measurements.

Frequency of Calibration

The frequency of calibration depends on how often the gauge is used and the conditions in which it is used. High-usage gauges and those used in harsh environments may require more frequent calibration.

Maintenance Tips

To keep pocket gauges in top condition, clean them regularly, store them in a protective case, and avoid dropping or exposing them to extreme temperatures. Regular calibration checks are also recommended.

Cleaning

Clean the gauge regularly to remove dust, dirt, and other contaminants that can affect its accuracy. Use a soft, lint-free cloth and a mild cleaning solution to avoid damaging the gauge.

Storage

Store the gauge in a protective case when not in use to prevent damage. Avoid exposing the gauge to extreme temperatures or humidity, as these conditions can affect its accuracy.

Handling

Handle the gauge with care to avoid dropping or damaging it. Avoid using the gauge for purposes other than measuring, as this can lead to wear and tear.

Technological Advancements

Smart Pocket Gauges

The integration of technology has led to the development of smart pocket gauges. These devices connect to smartphones and tablets, allowing for easy data transfer and analysis.

Connectivity Features

Smart pocket gauges can connect to mobile devices via Bluetooth or Wi-Fi, enabling real-time data transfer and remote monitoring. This feature is particularly useful for recording and analyzing measurements in the field.

Mobile Apps

Many smart pocket gauges come with companion mobile apps that provide additional functionality, such as data logging, trend analysis, and calibration reminders. These apps make it easier to manage and analyze measurement data.

Innovations in Design

Modern pocket gauges are designed with user-friendly features such as ergonomic grips, clear displays, and intuitive interfaces. These innovations make them easier to use and more accurate.

Ergonomic Design

Ergonomically designed pocket gauges reduce strain and improve accuracy. Features such as non-slip grips, easy-to-read displays, and lightweight construction enhance usability.

Advanced Displays

Many modern pocket gauges feature high-contrast, backlit displays that are easy to read in various lighting conditions. This improves accuracy and reduces the likelihood of reading errors.

User Reviews and Recommendations

Popular Brands

Some of the top brands for pocket tech gauges include Mitutoyo, Starrett, and Brown & Sharpe. These brands are known for their high-quality products and reliability.

Mitutoyo

Mitutoyo is a leading manufacturer of precision measuring instruments, known for their high-quality and innovative products. Their pocket gauges are widely used in various industries for their accuracy and durability.

Starrett

Starrett is another reputable brand, offering a wide range of measuring tools, including pocket gauges. Their products are known for their precision and reliability, making them a popular choice among professionals.

Brown & Sharpe

Brown & Sharpe is known for their high-quality measuring instruments and precision tools. Their pocket gauges are designed to provide accurate measurements and withstand the rigors of industrial use.

Choosing the Best Gauge

When selecting a pocket tech gauge, consider factors such as accuracy, durability, ease of use, and the specific requirements of your projects. Reading user reviews can provide valuable insights into the performance of different models.

Accuracy

Accuracy is a critical factor when choosing a pocket gauge. Look for gauges that provide precise measurements and have a low margin of error.

Durability

Durability is important, especially if the gauge will be used in harsh environments. Choose a gauge made from high-quality materials that can withstand wear and tear.

Ease of Use

Consider the ease of use when selecting a pocket gauge. Look for features such as clear displays, ergonomic design, and intuitive controls.

Ergonomics and Design

User-Friendly Features

Ergonomically designed pocket gauges reduce strain and improve accuracy. Features such as non-slip grips, easy-to-read displays, and lightweight construction enhance usability.

Non-Slip Grips

Non-slip grips provide a secure hold, reducing the likelihood of the gauge slipping and improving measurement accuracy. This is particularly important when working in wet or oily conditions.

Easy-to-Read Displays

High-contrast, backlit displays make it easier to read measurements in various lighting conditions. This reduces the likelihood of reading errors and improves overall accuracy.

Lightweight Construction

Lightweight gauges are easier to handle and reduce strain during use. This is especially important for professionals who use the gauge for extended periods.

Design Considerations

Manufacturers consider factors like balance, grip, and visibility when designing pocket gauges. These considerations ensure that the gauges are comfortable to use and provide clear, accurate readings.

Balance

A well-balanced gauge is easier to handle and provides more accurate measurements. Manufacturers design gauges with a balanced weight distribution to improve usability.

Visibility

Clear, easy-to-read markings and displays are essential for accurate measurements. Manufacturers use high-contrast colors and large fonts to enhance visibility.

Cost vs. Quality

Finding the Balance

While high-quality pocket gauges tend to be more expensive, they offer better accuracy and durability. It’s important to find a balance between cost and quality based on your needs and budget.

Assessing Your Needs

Consider the specific requirements of your projects when choosing a pocket gauge. If you need high precision and durability, it may be worth investing in a higher-quality gauge.

Budget Considerations

While it’s important to consider your budget, don’t sacrifice quality for cost. Investing in a high-quality gauge can save money in the long run by reducing the need for replacements and ensuring consistent, accurate measurements.

Long-Term Investment

Investing in a high-quality pocket gauge can save money in the long run by reducing the need for replacements and ensuring consistent, accurate measurements.

Durability and Longevity

High-quality gauges are built to last, providing reliable measurements over a long period. This reduces the need for frequent replacements and ensures consistent performance.

Accuracy and Reliability

High-quality gauges provide more accurate and reliable measurements, which can improve the quality of your work and reduce the likelihood of errors.

Educational Resources

Learning to Use Pocket Gauges

For beginners, many resources are available to learn how to use pocket tech gauges effectively. Online tutorials, workshops, and manufacturer manuals provide step-by-step instructions.

Online Tutorials

There are many online tutorials available that provide detailed instructions on how to use pocket gauges. These tutorials often include videos and illustrations to help beginners understand the basics.

Workshops and Training

Workshops and training programs offer hands-on instruction and guidance from experienced professionals. These programs can help beginners learn how to use pocket gauges accurately and effectively.

Advanced Techniques

For experienced users, advanced techniques and tips can enhance measurement accuracy and efficiency. Continuous learning and practice are key to mastering the use of pocket gauges.

Advanced Measurement Techniques

Experienced users can benefit from learning advanced measurement techniques that improve accuracy and efficiency. These techniques may include using multiple gauges, taking measurements from different angles, and applying mathematical calculations.

Ongoing Education

Continuing education is important for staying up-to-date with the latest advancements and techniques in measurement technology. Attending industry conferences, participating in online forums, and reading technical publications can help professionals stay informed.

Conclusion

Pocket tech gauges that measure in 16ths of an inch are essential tools in various industries, providing the precision needed for high-quality work. Understanding their features, applications, and maintenance requirements can help professionals choose the right gauge and use it effectively.

Recap of Key Points

- Pocket tech gauges provide precise measurements, often in 16ths of an inch, and are essential for many industries.

- Understanding the materials, types, and features of pocket gauges can help you choose the best tool for your needs.

- Regular calibration and maintenance are crucial for ensuring the accuracy and longevity of pocket gauges.

- Technological advancements, such as smart gauges and user-friendly designs, enhance the functionality and usability of these tools.

- Investing in a high-quality gauge can save money in the long run by reducing the need for replacements and ensuring consistent, accurate measurements.

- Educational resources, including online tutorials and workshops, are available to help beginners and experienced users alike master the use of pocket gauges.

Final Thoughts

Whether you are a woodworker, metalworker, engineer, or professional in another field, understanding and effectively using pocket tech gauges can significantly enhance the quality and precision of your work. By investing in a high-quality gauge, keeping it properly maintained, and staying informed about the latest advancements and techniques, you can ensure accurate measurements and achieve better results in your projects.

FAQs

What is a pocket tech gauge?

A pocket tech gauge is a small, portable measuring tool used to measure dimensions with high precision, often in 16ths of an inch.

How do I calibrate a pocket tech gauge?

Calibration involves comparing the gauge against a known standard and adjusting it as necessary. Regular calibration checks ensure accuracy.

What are the benefits of digital pocket gauges?

Digital pocket gauges offer easy reading, data storage, and connectivity to mobile devices, making them convenient and accurate.

Can pocket gauges be used in harsh environments?

Yes, many pocket gauges are designed to be durable and can withstand harsh conditions. Stainless steel gauges, in particular, are resistant to corrosion and wear.

How do I maintain my pocket tech gauge?

Regular cleaning, proper storage, and avoiding extreme temperatures or impacts can help maintain the accuracy and longevity of your pocket tech gauge.

What materials are pocket tech gauges made from?

Pocket tech gauges are typically made from stainless steel, aluminum, or hardened plastic, each offering different benefits in terms of durability and accuracy.

Are digital or analog pocket gauges better?

Both digital and analog gauges have their advantages. Digital gauges are easy to read and offer advanced features, while analog gauges are durable and do not require batteries.

What industries use pocket tech gauges?

Pocket tech gauges are used in various industries, including woodworking, metalworking, and engineering, for precise measurements and quality control.

How often should I calibrate my pocket tech gauge?

The frequency of calibration depends on how often the gauge is used and the conditions in which it is used. High-usage gauges and those used in harsh environments may require more frequent calibration.

Can I learn to use a pocket tech gauge online?

Yes, many online tutorials and resources are available to help beginners learn how to use pocket tech gauges effectively. Workshops and training programs also offer hands-on instruction.

This extensive guide aims to provide comprehensive information about pocket tech gauges, focusing on those that measure in 16ths of an inch. By understanding the features, applications, and maintenance requirements of these tools, professionals can make informed decisions and achieve accurate, high-quality results in their work.

1 Comment

Pingback: Pro-Reed: Unleashing the Power of Tech Tales